Free shipping is only available for local pickup.

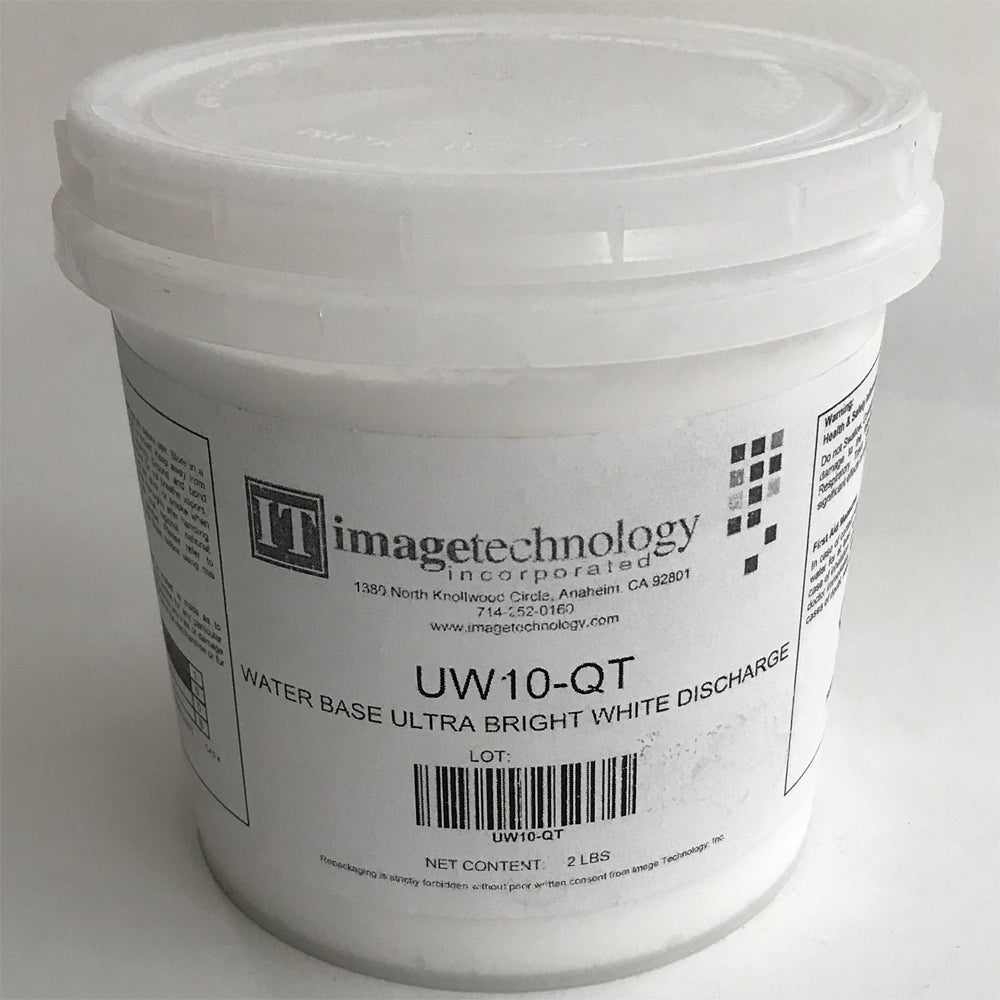

Image Technology UW-10 Water Based Ultra Bright White Discharge

- $ 22.45

- $ 22.45

- Unit price

- per

Couldn't load pickup availability

Description

xImage Tech UW-10 Ultra Bright White is an all aqueous water based screen printable ink which produces an exceptionally “bright white” print on dark fabrics with a very soft hand. UW-10 when used properly will “effectively displace” the dyes in the printed garment allowing the “printed color” to “take the place” of the fabrics dyed color, thus accomplishing what is commonly known in the industry as “discharge”.

UW-10 Ultra Bright White modifies the garment color by removing or discharging the garment color and replacing it with the new ink color. In simple terms, the discharge ink "bleaches" out the dye in the garment, thus allowing the pigment in the ink to absorb into the shirt fibers providing a dyed-in-the-fabric result.

Technical Information:The dye used in the garment must be dischargeable. The best results are achieved with garments that are 100% cotton and dyed with a reactive

dye.

The garment cannot have been over dyed (when fabric is re-dyed to another color). This often happens because of a shortage of a certain fabric color or, in many cases, because quality control rejected the fabric color. These rejected colors are then over dyed with a black dye, which will bring nightmares to life when trying to use discharge inks. The discharge ink might discharge the black dye - only to reveal a phantom color underneath.

Always test your garment first to see if it is suitable for discharge printing. If you are a major printer doing large volume printing, be aware that the garments you order from the mill are tracked by lot numbers, as it is possible that a completely different dye may be used from one lot to the next thus creating a color shift from print to print.

UW-10 Ultra Bright White can be printed through a variety of meshes from 60-230 monofilament polyester. Printing technique and environment is very important when printing through the higher mesh counts. Note: Variations in the ink deposit control the brightness of the final print.

UW-10 Ultra Bright White are water based, so it is imperative that you use water-resistant emulsion.

Drying/curing: It is in the dryer that the discharge effect takes place. A conveyor dryer with hot forced air is ideal for discharging/drying (electric, infrared or gas are acceptable). The longer the oven chamber, the better because of the slower belt speed needed for curing discharge inks. The recommended drying/curing temperature is between 310 degrees f. to 330 degrees f. and it generally requires 2 to 3 minutes dryer retention time to “complete the discharge”.

Mixing Instructions: Begin by adding from 5% to 10% by weight, of the “Discharge Agent” to the UW- Ultra Bright White, mix thoroughly, allow the mixture to “relax” for about 5 to 10 minutes prior to printing. Thin ink if necessary with plain tap water. Mix only the amount of ink that you will use in about a 4 hour period as the mixed ink has a “pot life”.

The information and specifications given in this Technical Data Sheet are based on our present knowledge which we believe to be accurate. Regardless, we provide no guarantee pertaining to their accuracy as we cannot anticipate every possible use of our products and because of the nature of the manufacturing process, as fabrics and other materials vary slightly. It is for these reasons our products are sold with no accompanying warranty and on the basis that our users will test the products themselves to ensure that they are suitable for their requirements.

Tech Sheet Download

Shipping & Return

xReturns Policy

You may return most new, unopened items within 30 days of delivery for a full refund. We'll also pay the return shipping costs if the return is a result of our error (you received an incorrect or defective item, etc.).

You should expect to receive your refund within four weeks of giving your package to the return shipper, however, in many cases you will receive a refund more quickly. This time period includes the transit time for us to receive your return from the shipper (5 to 10 business days), the time it takes us to process your return once we receive it (3 to 5 business days), and the time it takes your bank to process our refund request (5 to 10 business days).

If you need to return an item, simply login to your account, view the order using the "Complete Orders" link under the My Account menu and click the Return Item(s) button. We'll notify you via e-mail of your refund once we've received and processed the returned item.

Shipping

We can ship to virtually any address in the world. Note that there are restrictions on some products, and some products cannot be shipped to international destinations.

When you place an order, we will estimate shipping and delivery dates for you based on the availability of your items and the shipping options you choose. Depending on the shipping provider you choose, shipping date estimates may appear on the shipping quotes page.

Please also note that the shipping rates for many items we sell are weight-based. The weight of any such item can be found on its detail page. To reflect the policies of the shipping companies we use, all weights will be rounded up to the next full pound.

Related Products

Recently Viewed Products

- Choosing a selection results in a full page refresh.