Free shipping is only available for local pickup.

RUTLAND M3 YELLOW M34449 COLOR MATCHING MIXING INKS PLASTISOL OIL BASE FOR SILK SCREEN PRINTING

- $ 54.75

- $ 54.75

- Unit price

- per

Couldn't load pickup availability

Description

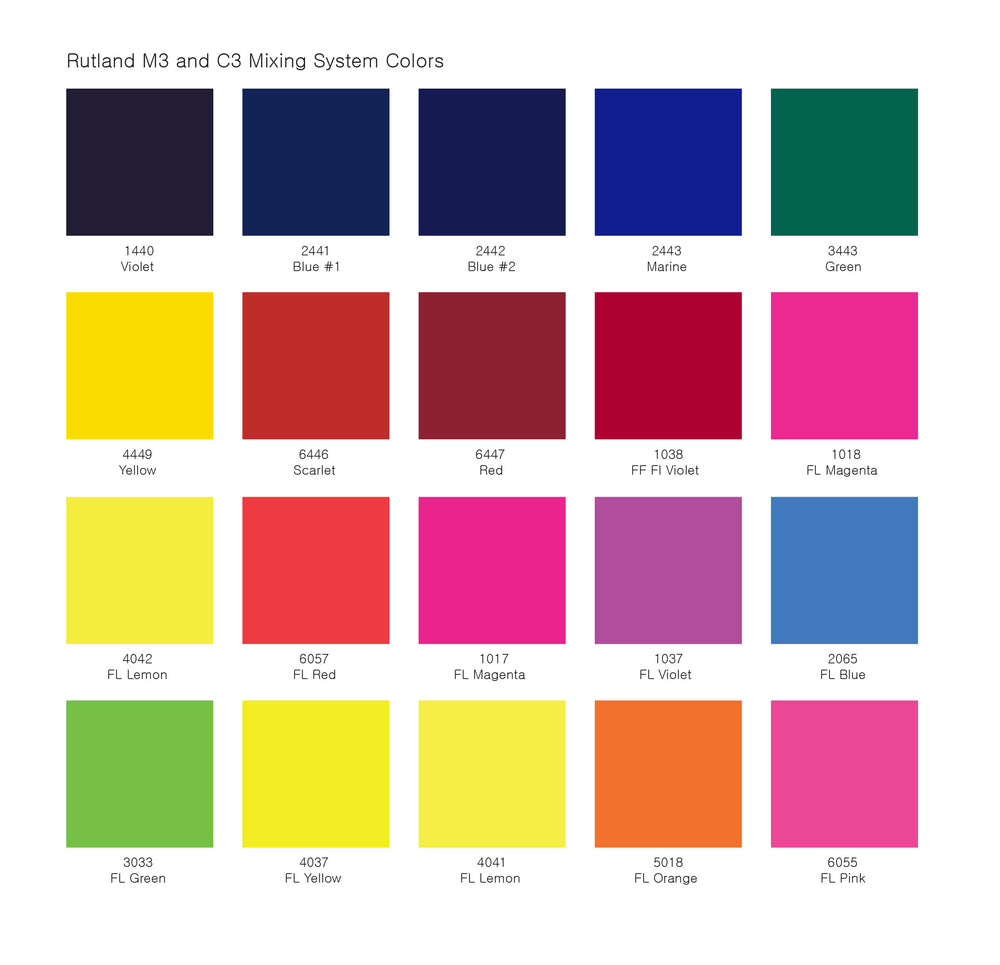

xRUTLAND M3 COLOR MATCHING MIXING INKS PLASTISOL OIL BASE FOR SILK SCREEN PRINTING

Finished Ink Mixing System

The M3 Finished Ink Mixing System is Rutland's popular and forgiving Pantone® certified color matching system. This high-performance, low-tack plastisol color mixing system is designed for printing on 100% cotton fabrics. It is an excellent color matching system for printing onto cotton/polyester blends when used with an added underbase with a low-bleed white or similar first-down product.

This system is designed for use with the IMS 3.0 ink management system. IMS 3.0 is a cloud-based solution for managing color and inventory in the textile screen-printing market. Offering tools for color creation and standardizing, IMS manages daily maneuvers in a highly functional ink room by providing color management and communication agility. Color chip images appear with formulations to help with visual communication. The new platform and updated functionality will continue to add functional support and innovation to the concept of total ink room management.

The M3 finished ink mixing system is a very opaque mixing system, offering excellent consistency on press throughout production runs. It is comprised of user-friendly inks, producing very bright colors and maintaining saturation during long production runs.

M3 Ink Mixing System is a non-phthalate finished ink mixing system. M3 colors directly replace the M2 and EM ink mixing colors. They are opaque resulting in excellent coverage on dark garments. The tackfree formula allows printing through a range of mesh counts without the need for a viscosity modifier. Use a white underlay when printing on dark fabrics for that extra "pop" in brightness. No buildup formulations ensure the highest print efficiencies without down time for wiping screens. Mix thousands of finished ink colors by choosing Pantone colors from our M2007 Ink Mixing Software or by custom mixing your own colors. NPT Low Bleed White underlay for printing on polyester/cotton blends. NPT Cotton White underlay for printing on 100% cotton. Claira NPT Barrier Base (Dyno Grey) available for printing on 100% polyester Instructions Printing on White Garments: Mix per formulation or by eye to achieve brilliant colors on 100% cotton whites. For extremely soft-hand prints, mix finished color up to 1:1 with Claira ES0250 NPT Chino Base. Printing on Dark Garments or over an underlay: When printing on dark garments, mix per formulation or custom blend to achieve brilliant colors over an underlay. Use the NPT Low Bleed White on poly/cotton blends and the ES0266 NPT Barrier Base when printing on 100% polyester Puff designs: Mix 10-15% of Claira NPT Puff Additive to any formulated Claira™ Color to create a puff ink.

Recommendation Claira Colors™, bases, modifiers and additives should be mixed in clean vessels using clean mixer blades and utensils. Any contamination from other ink sources or non-approved additives could make Claira Colors™ test positive for the restricted phthalates. Do not dry clean, bleach, or iron the printed image. Note to 100% cotton users: With low bleed ink, 100% cotton could produce a ghost image. Claira M39000 NPT LB NG RETRO WHITE is a low-bleed ink that is formulated to print on cotton or polyester cotton without causing a ghost image. M39000 NPT LB NG RETRO WHITE is not recommended for 100% polyester. Use Claira Barrier Base for 100% polyester.

Shipping & Return

xReturns Policy

You may return most new, unopened items within 30 days of delivery for a full refund. We'll also pay the return shipping costs if the return is a result of our error (you received an incorrect or defective item, etc.).

You should expect to receive your refund within four weeks of giving your package to the return shipper, however, in many cases you will receive a refund more quickly. This time period includes the transit time for us to receive your return from the shipper (5 to 10 business days), the time it takes us to process your return once we receive it (3 to 5 business days), and the time it takes your bank to process our refund request (5 to 10 business days).

If you need to return an item, simply login to your account, view the order using the "Complete Orders" link under the My Account menu and click the Return Item(s) button. We'll notify you via e-mail of your refund once we've received and processed the returned item.

Shipping

We can ship to virtually any address in the world. Note that there are restrictions on some products, and some products cannot be shipped to international destinations.

When you place an order, we will estimate shipping and delivery dates for you based on the availability of your items and the shipping options you choose. Depending on the shipping provider you choose, shipping date estimates may appear on the shipping quotes page.

Please also note that the shipping rates for many items we sell are weight-based. The weight of any such item can be found on its detail page. To reflect the policies of the shipping companies we use, all weights will be rounded up to the next full pound.

Related Products

Recently Viewed Products

- Choosing a selection results in a full page refresh.